Understanding Warehouse Roof Waterproofing

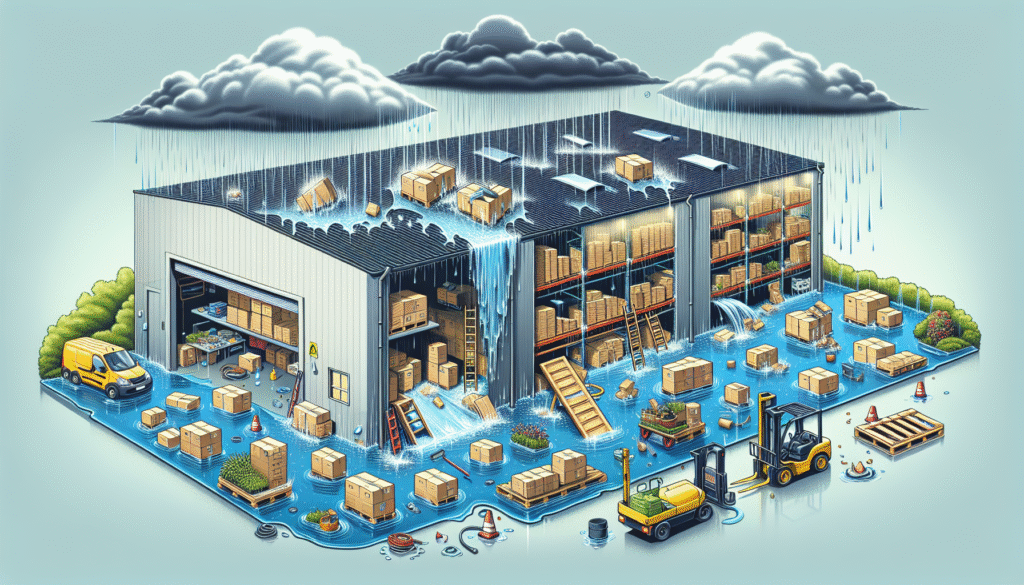

When it comes to managing large-scale storage facilities, one of the most critical concerns for property managers and developers is ensuring the building is adequately protected from the elements. Roof waterproofing plays a vital role in this equation, especially with the unpredictability of weather patterns. Water damage can compromise structural integrity, affect inventory, and lead to costly repairs. This is where hotmelt roof waterproofing emerges as a powerful solution.

What is Hotmelt Roof Waterproofing?

Hotmelt technology refers to an advanced roof waterproofing technique that utilizes a molten membrane applied in liquid form to create a seamless, durable, and highly effective barrier against water infiltration. This method is especially popular because it can adapt to complex roof designs and offers superior protection.

Components of Hotmelt Systems

- Primer: Prepares the surface and ensures proper adhesion of the membrane.

- Melted Membrane Layer: The primary layer applied in liquid form which hardens to create a seamless coat.

- Reinforcement Layer: Provides additional durability, typically embedded within the hot melt layer for long-term effectiveness.

- Protection Layer: Shields the membrane from physical damage, often used in trafficable areas.

Hotmelt Application Process

The application process of hotmelt waterproofing involves precise handling and professional expertise to ensure it delivers its maximum benefits. The substrate is first primed, and then the hotmelt membrane is heated to a liquid state before being applied. Reinforcement may be added for additional strength, followed by a protection layer if necessary. This multi-layered system guarantees a robust water-resistant surface.

Advantages of Hotmelt Roof Waterproofing

Choosing hotmelt roof waterproofing comes with several notable advantages over traditional methods, making it an attractive option for developers and property managers alike.

Durability and Longevity

One of the prime benefits of hotmelt systems is their exceptional durability. Designed to withstand extreme weather conditions, they provide an effective barrier that remains intact over time. The lifecycle of a hotmelt roof often surpasses that of other waterproofing methods, offering decades-long performance without significant wear and tear.

Flexibility and Adaptability

Hotmelt roofing systems are incredibly versatile and can be tailored to fit any roof configuration, including those with intricate designs. This flexibility makes it an ideal choice for modern architectural projects, where unique roofing patterns are common.

Seamless and Monolithic Nature

The application of hotmelt results in a continuous, monolithic membrane without seams or joints where leaks might occur. This seamless nature minimizes maintenance needs and significantly enhances the integrity of the waterproof seal.

Environmental and Cost Efficiency

- Eco-friendly: Many hotmelt systems contain recycled materials, reducing environmental impact.

- Cost-effective: While initial installation costs may be higher, their durability and low maintenance make them more economical in the long run.

Considerations Before Installation

Before opting for hotmelt waterproofing, there are several factors property managers and developers should consider to ensure it’s the best fit for their needs:

Roof Condition

Assess the current state of the roof. Any existing damage or degradation needs to be addressed to ensure the hotmelt system can be applied effectively. A thorough inspection by a qualified professional is recommended prior to application.

Professional Installation

Due to the complexity and specialized nature of hotmelt roof waterproofing, it’s crucial to employ experienced installers who are skilled in handling the materials and executing the technique correctly. This not only guarantees optimal results but prevents potential issues that could arise from improper installation.

Maintenance and Inspection

Even with a robust system such as hotmelt, regular inspections and maintenance contribute to the longevity and effectiveness of the waterproofing. Here’s how to ensure your system remains effective:

Regular Inspections

Schedule routine checks to inspect the condition of the waterproofing membrane. Look for signs of wear, membrane lifting, or any physical damage that may require repair.

Preventative Measures

- Clear debris from the roof to prevent clogs and standing water.

- Inspect sealing at penetrations and flashings to prevent leaks.

Summary

Hotmelt roof waterproofing is an optimal solution for warehouse and hall owners seeking durable, effective protection against water infiltration. Its seamless, adaptable nature provides a long-lasting barrier suited for any roof design, making it ideal for modern structures. Despite its higher initial cost, the longevity and reduced maintenance make it a cost-effective choice over time. By ensuring professional installation and regular maintenance, property managers can maximize the benefits of hotmelt systems, safeguarding their buildings and contents for years to come.