Understanding Hotmelt Roof Waterproofing

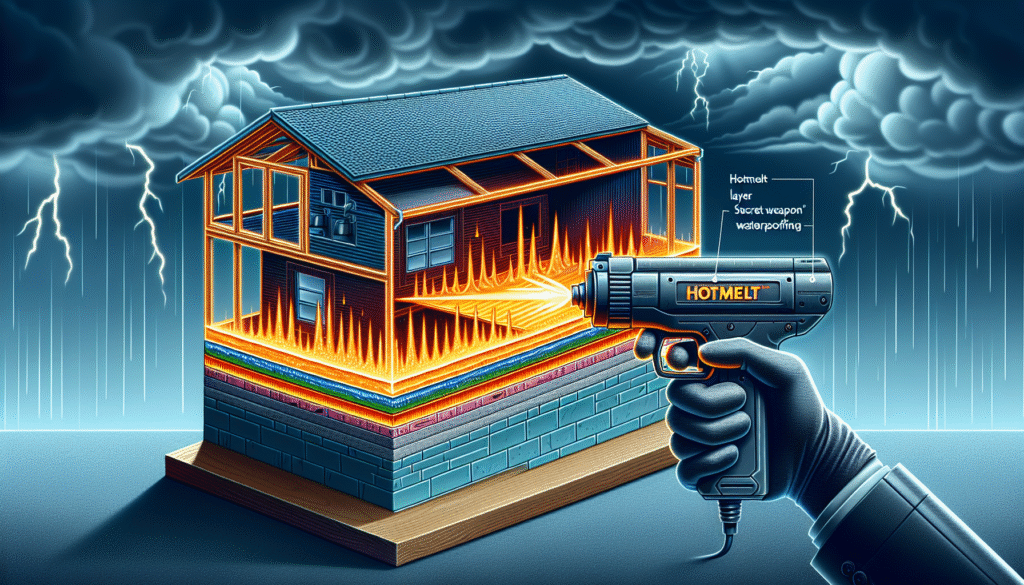

When considering roof waterproofing solutions, one technology stands out: hotmelt waterproofing. This innovative method offers unparalleled benefits, making it a preferred choice for hall and warehouse owners and property managers seeking durable and effective insulation solutions. In this comprehensive guide, we’ll delve into the specifics of hotmelt roof waterproofing, exploring its advantages over other methods and why it could be the secret weapon you’ve been looking for.

How Hotmelt Roof Waterproofing Works

Hotmelt waterproofing is a liquid-applied system that creates a seamless and flexible membrane over a roof structure. The process involves heating a specially formulated polymer-modified bitumen to high temperatures, which is then directly applied to the substrate. As it cools, it forms a strong, durable layer that is both adhesive and fully bonded. This technique is particularly effective when used on flat or low-pitched roofs.

The Application Process

- Substrate Preparation: Before any hotmelt material is applied, the roof substrate must be thoroughly cleaned and primed. This step ensures optimal adhesion and longevity of the waterproofing layer.

- Heated Application: The polymer-modified bitumen is heated in specialist equipment to maintain a consistent, high temperature, ensuring it remains in liquid form during application.

- Layering: The hotmelt is applied in layers, often with reinforcing materials such as polyester fleece added between coats to enhance its strength and durability.

- Curing: Once applied, the hotmelt cools and cures, forming a robust, flexible membrane that is bonded to the roof structure.

The Flexibility of Usage

One of the most significant advantages of hotmelt waterproofing systems is their adaptability. They can be used on new builds as well as roof refurbishments. This flexibility makes them an excellent choice for developers and property managers looking to upgrade or maintain their buildings.

The Advantages of Hotmelt Waterproofing

Choosing hotmelt waterproofing for your hall or warehouse roof offers numerous benefits that set it apart from traditional waterproofing methods. Here’s why it’s considered a superior option:

Durability and Longevity

Hotmelt systems are designed to last for the lifetime of the building. Once cured, they form an incredibly tough and resilient barrier that is resistant to water ingress, environmental chemicals, and temperature fluctuations. This durability reduces the need for frequent maintenance, offering long-term cost savings.

Seamless Application

The hotmelt process creates a continuous, completely seamless waterproofing layer. Unlike membrane systems that require joints and seams, hotmelt applications eliminate common points of failure, reducing the risk of leaks.

Environmental and Cost Benefits

Hotmelt systems are also praised for their environmental benefits. Many hotmelt products are solvent-free and contribute to sustainable building practices. Moreover, the robustness of the material ensures lower energy consumption throughout its lifetime due to its effective insulation properties.

Comparison with Other Waterproofing Methods

While there are numerous waterproofing options available, hotmelt systems offer unique advantages that make them a worthwhile investment. Let’s compare hotmelt waterproofing with other common methodologies:

Liquid Applied Membranes vs. Hotmelt

Liquid applied membranes are popular because they are easy to apply and can cover complex roof designs. However, they often rely on volatile organic compounds (VOCs) and solvents, which can pose environmental concerns. Meanwhile, hotmelt systems offer the same level of coverage without the downsides of VOC emissions.

Traditional Asphalt and Felt Systems vs. Hotmelt

Asphalt and felt systems are traditional methods widely used for their low initial cost. However, they tend to suffer from brittleness over time, leading to cracks and leaks. Hotmelt, on the other hand, remains flexible and intact over long periods, reducing the need for costly repairs and replacements.

Ideal Scenarios for Hotmelt Waterproofing Use

Understanding when to use hotmelt waterproofing can further optimize its benefits. Hotmelt systems are ideal for:

- Heavy Foot Traffic Areas: Its durability makes it perfect for roofs that require occasional access for maintenance or have mechanical installations.

- Green Roofs: The robust waterproof membrane makes it excellent for green roof setups, where additional layers of earth and vegetation are added above the waterproofing layer.

- New Builds and Refurbishments: Whether installing a roof on a new building or upgrading an existing one, hotmelt systems offer reliable performance.

Summary

Hotmelt roof waterproofing stands out as a superior choice for those managing halls and warehouses, thanks to its durability, seamless application, and environmental benefits. Its flexible and robust application method solves many weaknesses inherent in traditional waterproofing systems. By choosing hotmelt, property managers can ensure long-lasting protection against water ingress and reduce maintenance costs, making it a compelling option for any property requiring reliable waterproofing solutions.