Understanding Hotmelt Roof Waterproofing

Hotmelt roof waterproofing is rapidly gaining popularity among hall and warehouse owners, developers, and property managers. Known for its durability and efficiency, this waterproofing method is redefining how commercial spaces maintain optimal protection against the elements. Hotmelt technology involves applying a rubberized asphalt material, heated to a specified temperature, directly onto the roof substrate to form a seamless, flexible, and highly durable membrane that defends against water infiltration.

Choosing the right waterproofing solution for your commercial building’s roof is essential for long-term performance and protection. This article delves into the benefits of hotmelt roof waterproofing, its application process, and how it stands against traditional methods. By choosing hotmelt waterproofing, you ensure a robust, enduring protection for your asset.

The Benefits of Hotmelt Roof Waterproofing

Long-Term Durability

One of the most compelling advantages of hotmelt roof waterproofing is its long-term durability. Unlike other waterproofing methods that may require frequent maintenance, a properly applied hotmelt system can last over 25 years. It can withstand extreme weather conditions, temperature fluctuations, and UV radiation without cracking or deteriorating. This lasting performance means fewer repairs and lower maintenance costs.

Seamless Application

Hotmelt waterproofing is applied as a continuous layer, creating a seamless membrane on the roof surface. This eliminates the weak points often found in other systems where seams or joints can be prone to leaks. A seamless application ensures comprehensive coverage and protection across the entire roof, safeguarding against water ingress in every crevice.

Adaptability to Various Roof Designs

The flexibility of hotmelt systems makes them ideal for complex roof designs. Whether your roof has numerous penetrations, angles, or varied substrates, hotmelt can adapt to these challenges. This adaptability ensures a consistent application across different types and configurations of roof structures.

Hotmelt Waterproofing vs. Traditional Methods

Comparing Hotmelt to Bitumen Felt

Traditional bitumen felt roofing is known for its relatively short lifespan and susceptibility to weathering. Hotmelt waterproofing surpasses these limitations with its more durable and weather-resistant characteristics. Where bitumen may crack or require additional seams and joints, hotmelt provides a stable and seamless solution.

Hotmelt versus TPO and EPDM Membranes

Thermoplastic Olefin (TPO) and Ethylene Propylene Diene Monomer (EPDM) are other popular waterproofing choices. However, these membranes often necessitate multiple layers and complex installations. Hotmelt, conversely, provides a rich single-layer solution that is simpler to install, yet matches or exceeds these membranes in both durability and lifespan.

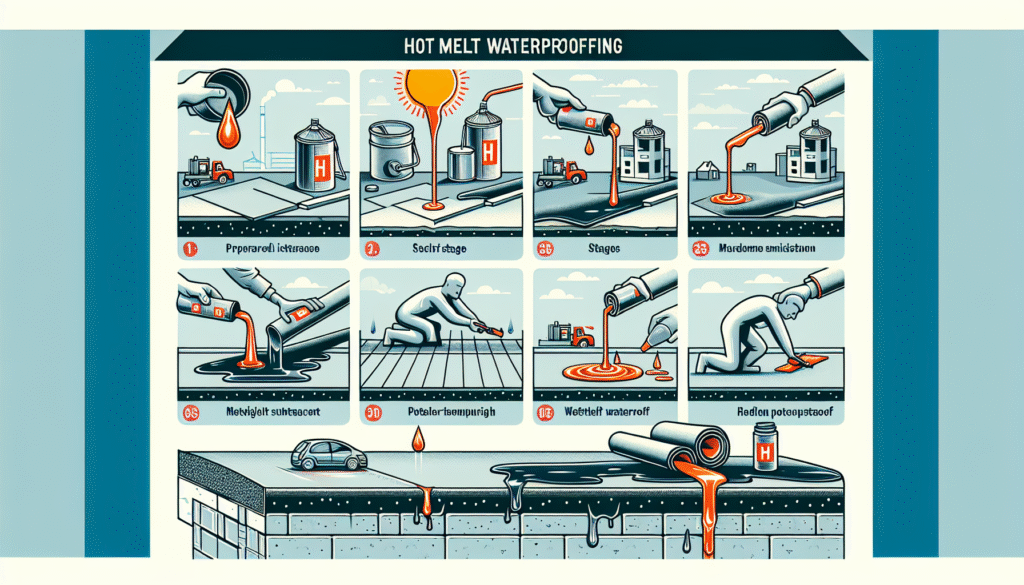

Application Process of Hotmelt Roof Waterproofing

Roof Preparation

The first step in applying hotmelt waterproofing is thorough roof preparation. This involves cleaning the surface of any debris, repairing any existing damage, and ensuring the roof is dry. Proper preparation is crucial to ensure optimal adhesion of the hotmelt material, which is key to its long-term performance.

Application Technique

Professional applicators use specialized equipment to heat the rubberized asphalt material, which is then applied directly to the prepared substrate. The material is spread evenly to ensure a uniform coverage. Once applied, the hotmelt cools and cures, forming a robust, watertight barrier. Proper installation by experienced contractors is essential to capitalize on the material’s full potential.

Curing and Finishing

After application, the hotmelt layer requires a short period to cure fully. Once cured, the membrane is durable and ready to receive any additional protective layers or aesthetic finishes, such as green roofs or gravel stones, tailored to the specific needs or design preferences of the building.

Environmental Considerations

Sustainability

Hotmelt roofs promote sustainability as they are comprised of recycled materials, and their durability results in less frequent replacements, minimizing waste. Property developers aiming for green certifications will find hotmelt roofing aligned with their sustainability goals.

Energy Efficiency

The use of hotmelt systems can contribute to a building’s energy efficiency. The insulation properties enhance temperature regulation, keeping interiors cooler in summer and warmer in winter, leading to potential savings on heating and cooling costs.

Summary

Hotmelt roof waterproofing presents a superior choice for those seeking a robust, versatile, and enduring solution for commercial buildings. Its seamless application, resilience against weather extremes, and adaptability to various designs place it head and shoulders above traditional methods. When considering waterproofing options, hall and warehouse owners, developers, and property managers will discover that hotmelt delivers unmatched protection, contributing to both sustainability and energy efficiency. With its long lifespan and high performance, hotmelt waterproofing not only enhances building integrity but also offers peace of mind regarding roof maintenance and repair costs.