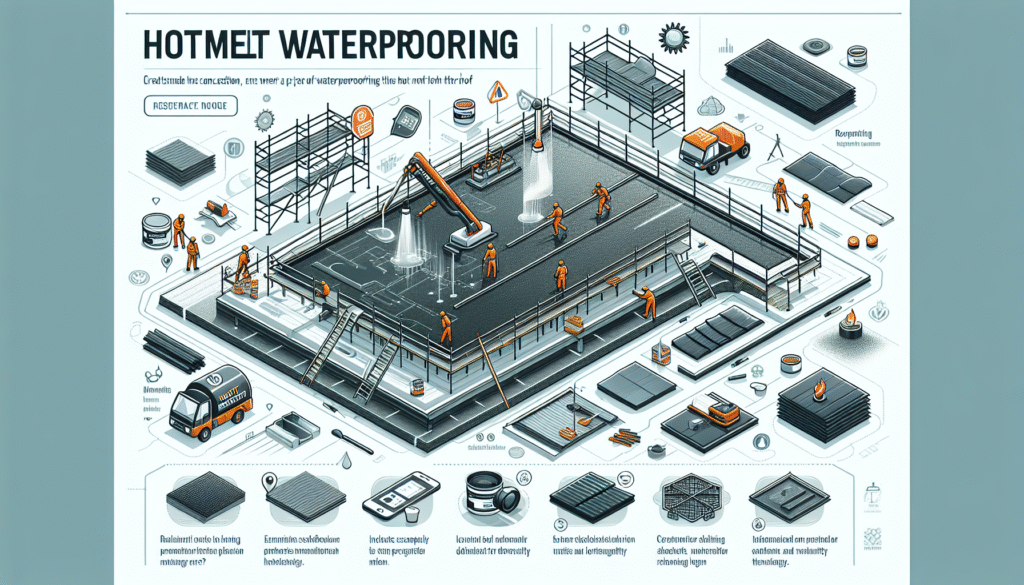

Unveiling Hotmelt Waterproofing: A Comprehensive Solution for Roof Longevity

When it comes to protecting large commercial roofs, such as those found on warehouses and distribution centers, durability and efficiency are paramount. For hall and warehouse owners, developers, and property managers, hotmelt roof waterproofing offers a cutting-edge solution that significantly enhances roof longevity and performance. This advanced technology provides a seamless, robust, and adaptable barrier against water infiltration, setting it apart from traditional insulation methods.

Understanding Hotmelt Waterproofing

Hotmelt waterproofing involves the application of a monolithic, fully-adhered roofing membrane that is heated and applied as a liquid to form a continuous, seamless layer. This method utilizes a blend of bitumen, modified with resins, to create a durable and pliable waterproofing solution that adheres to the roof substrate with high efficiency.

The Application Process

– **Surface Preparation:** The roof substrate must be cleaned thoroughly to ensure optimal adhesion of the hotmelt material.

– **Heating and Application:** The hotmelt material is heated to a specific temperature and applied directly onto the surface. This ensures a flush bond, minimizing any potential for water seeping through seams or joints.

– **Cooling and Solidification:** Once applied, the hotmelt cools rapidly, solidifying into a robust, seamless layer that conforms to the contours of the roof.

The Materials Used

The composition of hotmelt systems typically includes:

– **Polymer-Modified Bitumen:** Enhances flexibility and durability.

– **Reinforcing Fabric:** Added for extra strength and stability.

– **Protection and Bonding Layers:** These layers ensure compatibility with various substrates and provide additional waterproofing capabilities.

Advantages of Hotmelt Waterproofing

The benefits of hotmelt waterproofing are manifold, making it a preferred choice for commercial and industrial buildings.

Durability and Longevity

Hotmelt systems are renowned for their long lifespan. Here’s why:

– **Resistance to Water and Weather:** Hotmelt systems offer unrivaled protection from diverse weather conditions, including intense rain, snow, and UV radiation.

– **Robustness:** Unlike traditional methods, hotmelt systems do not develop weak points over time, ensuring consistent protection throughout the roof’s lifetime.

Cost-Effectiveness

While initial installation might come at a higher price, the long-term benefits include:

– **Reduced Maintenance Costs:** With fewer repairs needed over the years, facility managers can significantly save on maintenance expenses.

– **Long-Term Investment:** Hotmelt waterproofing greatly extends the roof’s life, offering better returns on investment in the long run.

Environmental and Energy Benefits

With increased focus on sustainability, hotmelt systems contribute to greener building practices.

– **Improved Energy Efficiency:** The waterproofing layer acts as an additional insulator, reducing energy consumption for building heating and cooling.

– **Material Recyclability:** Many hotmelt materials are recyclable, supporting eco-friendly construction and renovation initiatives.

Hotmelt vs. Other Waterproofing Methods

To truly appreciate hotmelt waterproofing’s advantages, it is crucial to compare it with alternative methods such as single-ply membranes and built-up roofing (BUR).

Single-Ply Membranes

While popular, single-ply membranes often face issues like material shrinkage and seams that can lead to leaks. In contrast:

– **Hotmelt provides a seamless finish**, greatly reducing the risk of leaks.

– **Durability concerns** associated with single-ply are minimized with hotmelt, which is resistant to punctures and tearing.

Built-Up Roofing (BUR)

BUR involves multiple layers of bitumen and reinforcing fabrics, which can be cumbersome to install.

– **Hotmelt offers a quicker and less labor-intensive installation** process, which means less disruption to business operations.

– **Lightweight in comparison**, hotmelt adds less structural load to the building.

Choosing the Right Contractor

The installation of a hotmelt roofing system requires expertise and precision. When selecting a contractor, consider the following criteria:

Experience and Credentials

– Ensure the contractor has extensive experience with hotmelt systems.

– Check for proper licensing and certifications relevant to waterproofing and roofing.

Previous Project Reviews

– Request references from past projects with similar specifications.

– Investigate customer feedback to gauge reliability and quality of work.

Detailed Proposals

– A qualified contractor should provide a detailed proposal that includes timelines, costs, and scope of work.

– Look for warranties that guarantee workmanship and material quality.

Summary

Hotmelt roof waterproofing stands out as a superior solution for industrial and commercial buildings. Its seamless, robust, and durable finish offers remarkable protection against the elements, extending the lifespan of your roof. By choosing this innovative method, facility managers and developers benefit from reduced maintenance costs, impressive energy efficiency, and enhanced sustainability. With the right contractor, hotmelt systems ensure longevity and resilience, redefining what is possible in roof waterproofing solutions.