Understanding Hotmelt Roof Waterproofing

Hotmelt roof waterproofing has emerged as a leading solution in the architectural world, particularly for those managing large-scale properties like halls and warehouses. This advanced technology presents a long-lasting and efficient option that not only protects your investments but also enhances the structural integrity of buildings.

Whether you’re a developer or a property manager, understanding the fundamentals of hotmelt roof waterproofing can set you apart in maintaining and preserving valuable assets.

What is Hotmelt Roof Waterproofing?

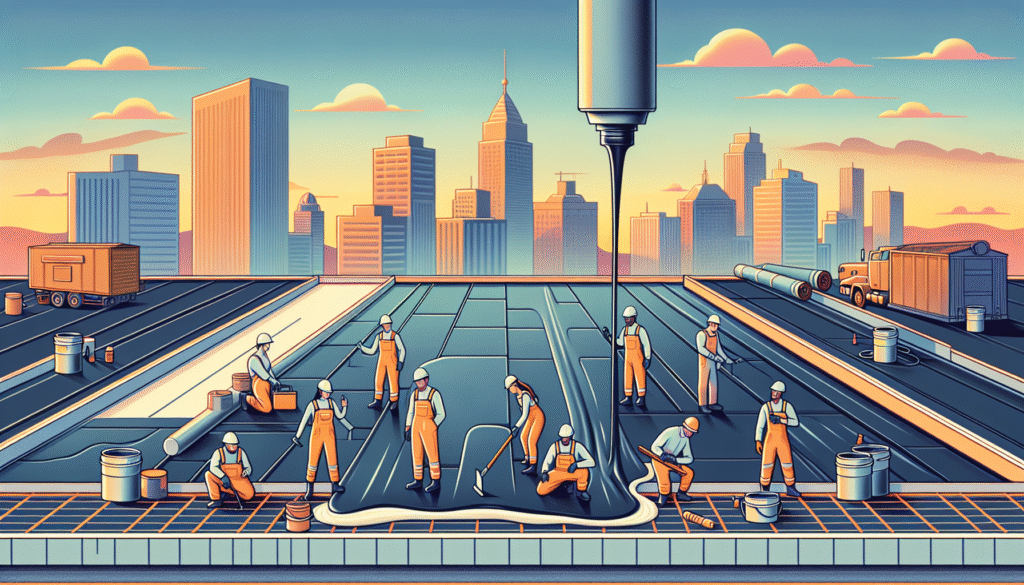

Hotmelt roof waterproofing is a roofing system that involves the application of a heated liquid membrane, usually composed of a polymer-modified bitumen material. This liquid is applied directly to the roof substrate to create a seamless and durable waterproof barrier.

The Components of Hotmelt Systems

The typical hotmelt system consists of several layers, including:

– **Base Layer:** Usually made up of structural decking to provide a stable foundation.

– **Primer:** Applied to enhance the bond between the substrate and the waterproofing layer.

– **Waterproofing Layer:** The hotmelt itself, applied in a molten form to provide an impermeable seal.

– **Insulation Layer:** Ensures thermal efficiency by reducing heat loss or gain.

– **Protection and Surfacing Layer:** Protects the waterproofing materials from damage and environmental wear.

Advantages of Hotmelt Roof Waterproofing

Implementing hotmelt roof waterproofing offers several benefits that can vastly improve the functionality and longevity of your building’s roof.

Durability and Longevity

One of the primary benefits of hotmelt roof waterproofing is its incredible durability. The seamless and fully bonded nature of hotmelt membranes provides a robust defense against water ingress and environmental factors, often lasting over 40 years with proper maintenance.

Flexibility and Versatility

Hotmelt systems are adaptable to various designs and can be used on both flat and low-sloped roofs. This flexibility makes them ideal for complex architectural features and modifications, ensuring a custom fit for any structure.

Environmentally Friendly Solution

Hotmelt systems often use recycled materials, reducing the carbon footprint associated with new roofing installations. Their thermal efficiency also contributes to lower energy usage for heating and cooling, aligning with sustainable building objectives.

Comparing Hotmelt to Other Waterproofing Solutions

To truly appreciate the value of hotmelt roof waterproofing, it is essential to compare it with other common methods like EPDM, TPO, and PVC roofing.

EPDM vs. Hotmelt

EPDM membranes, typically rubber-based, are known for flexibility but can suffer from seam issues over time. In contrast, hotmelt’s seamless application leaves no joints for water to penetrate, providing superior water resistance.

TPO/PVC vs. Hotmelt

While TPO and PVC are lightweight and reflective, they can be prone to cracking in fluctuating temperatures. Hotmelt’s formulation provides greater resilience to temperature extremes, making it a more stable solution for diverse climates.

Implementing Hotmelt Roof Waterproofing in Warehouses and Halls

For decision-makers in charge of large-scale properties, adopting hotmelt roof waterproofing ensures that their structures not only meet but exceed modern building standards.

Here are some key considerations when implementing hotmelt solutions:

– **Professional Installation:** Engage with certified contractors who specialize in hotmelt systems to ensure a top-quality finish.

– **Regular Maintenance:** Consistent inspections and minor maintenance can extend the lifespan of the hotmelt system.

– **Cost Considerations:** While initially more expensive than some alternatives, hotmelt systems offer a favorable lifecycle cost due to fewer repairs and replacements.

Summary

In conclusion, hotmelt roof waterproofing represents a superior choice for those seeking durable, flexible, and environmentally friendly roofing solutions. Its unmatched longevity and adaptability make it an ideal option for large properties like warehouses and halls, safeguarding them against the wear and tear of time and elements. By choosing hotmelt technology, property managers and developers can ensure robust protection and lasting peace of mind for their valuable structures.