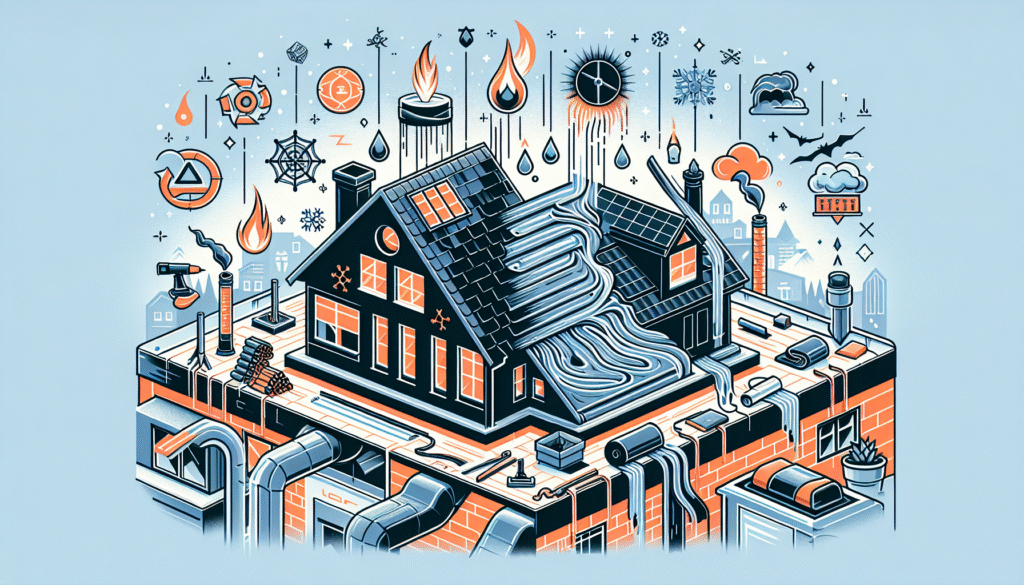

Introduction to Hotmelt Roof Waterproofing

Hotmelt roof waterproofing is revolutionizing the way we think about building and maintaining commercial roofs, offering unprecedented durability and protection against the elements. For hall and warehouse owners, developers, and property managers, choosing the right insulation solution is crucial to ensure the longevity and reliability of their buildings. In this comprehensive guide, we will explore how hotmelt technology stands out from traditional methods, providing a lasting solution for your roofing needs.

The Science Behind Hotmelt Technology

Hotmelt roof waterproofing involves the application of a multi-layered system, combining high-performance, polymer-modified bitumen with reinforcement layers, to create a seamless, monolithic waterproof barrier.

The Composition of Hotmelt Systems

The core of a hotmelt system is the bitumen, which is heated until liquefied and then applied in layers to achieve optimal thickness. This bitumen is polymer-modified, enhancing its performance, flexibility, and resistance to temperature changes. The process includes:

1. **Base Layer**: A priming solution to prepare the roof surface.

2. **Reinforcement Layer**: Typically a fiberglass or polyester membrane to enhance durability.

3. **Hotmelt Layer**: The heated bitumen, applied in multiple coats for maximum protection.

4. **Surface Layer**: A variety of options, including aggregate surfaces or finishes tailored to the specific environmental needs.

Advantages Over Traditional Methods

Hotmelt systems offer numerous benefits compared to conventional waterproofing techniques. Here are some reasons why property managers and developers are turning to hotmelt technology:

– **Seamless Application**: Unlike traditional methods that use sheets or membranes prone to seam failure, hotmelt systems offer a monolithic layer, reducing potential leak points.

– **Adaptability**: The system can accommodate complex roof geometries, providing a customized fit.

– **Longevity**: With fewer failure points and high material quality, hotmelt systems last much longer than many traditional alternatives.

– **Environmental Resistance**: Hotmelt formulations are designed to withstand extreme weather conditions, maintaining flexibility and integrity even in severe temperatures.

Cost-Effectiveness and Maintenance

While initial costs may seem higher compared to traditional materials, hotmelt roof waterproofing offers significant savings over time.

Investment Returns

– **Reduced Repair Costs**: Thanks to its durability, hotmelt technology greatly reduces the need for frequent repairs and maintenance.

– **Energy Efficiency**: The material’s insulating properties can lead to energy savings, as less heating or cooling is needed.

– **Long-Term Value**: With a lifespan that often exceeds other waterproofing systems, the long-term savings can be substantial.

Maintenance Requirements

Routine inspections are essential to ensure your roofing system continues to perform optimally. However, hotmelt systems generally require less maintenance than traditional membranes, thanks to their robust construction.

– **Visual Inspections**: Identifying damage or wear early can prevent costly repairs.

– **Professional Assessments**: Engaging with roofing professionals periodically ensures the system remains in top condition.

Environmental and Safety Considerations

Hotmelt roof waterproofing is not only effective but also aligns with modern environmental standards and safety regulations.

Sustainability Benefits

– **Low Carbon Footprint**: The production of hotmelt systems leverages materials that have a lower environmental impact.

– **Recyclable Materials**: Components used in hotmelt technology are often recyclable at the end of their life cycle.

Enhanced Safety Standards

– **Fire Resistance**: Many hotmelt systems are designed to resist fire spread, contributing to overall building safety.

– **No Volatile Compounds**: Once cured, hotmelt materials do not emit harmful volatile organic compounds (VOCs).

Case Studies: Success Stories in Hotmelt Application

Across the world, numerous commercial properties have successfully integrated hotmelt roof waterproofing, demonstrating its reliability and effectiveness.

Warehouse Revamp

A leading logistics company recently refurbished its aging warehouse roof using hotmelt waterproofing. The results included:

– Enhanced weather resistance, reducing heat loss.

– Significant cut in energy expenditure.

Retail Complex Renovation

A major retail center opted for hotmelt technology during its expansion, leading to:

– Improved roof lifespan and reduced operational costs.

– Increased tenant satisfaction due to minimized disruptions from roofing issues.

Summary

Hotmelt roof waterproofing represents a game-changing advancement in building maintenance, offering unmatched durability, cost-effectiveness, and environmental friendliness. By eliminating traditional weaknesses such as seams and improving on adaptation capabilities, hotmelt technology gives hall and warehouse owners, developers, and property managers a reliable and sustainable insulation solution. Investing in hotmelt can lead to long-term savings, reduced maintenance needs, and better energy efficiency, making it a smart choice for any commercial building looking to protect its assets while decreasing its environmental impact.