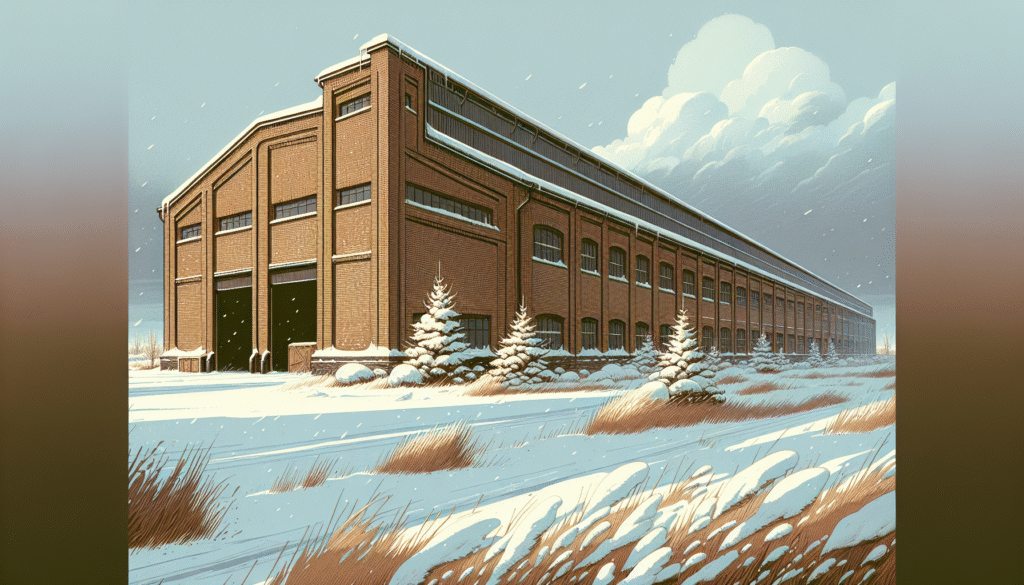

Is Your Warehouse’s Roof Winter-Ready? Discover the Strength of Hotmelt Roof Waterproofing

As winter approaches, ensuring your warehouse roof is prepared to withstand the harsh conditions is paramount. One of the most effective solutions for maintaining a dry, protected environment within your warehouse is hotmelt roof waterproofing. This comprehensive guide will explore why hotmelt roofing is an excellent choice for warehouse owners, developers, and property managers looking for durable and efficient insulation solutions.

Understanding Hotmelt Roof Waterproofing

Hotmelt roof waterproofing is a proven technology that involves the application of a hot-applied, rubberized bitumen membrane to provide a continuous waterproof barrier. This method offers several advantages over more traditional roofing solutions.

Benefits of Hotmelt Roofing

Among the many advantages of hotmelt roofing, durability stands out. This solution is designed to last for decades without needing significant maintenance, offering substantial long-term cost savings. The seamless nature of hotmelt membranes eliminates the risk of water ingress, thus protecting the structural integrity of your warehouse.

Additionally, hotmelt systems are highly adaptable to various building designs and can accommodate penetrations and complex architectural details with ease. This flexibility makes them an ideal choice for modern warehouse designs, which often include complex HVAC and utility installations.

Comparing Hotmelt with Other Roofing Solutions

When compared to other roofing solutions like EPDM, TPO, or traditional felt systems, hotmelt presents superior resistance to temperature fluctuations and ultraviolet rays. This resistance reduces the risk of cracking and deterioration over time. Furthermore, hotmelt systems provide outstanding performance in extreme weather conditions, making them particularly suitable for environments subject to harsh winters.

Preparing Your Warehouse for Winter with Hotmelt

Ensuring your warehouse is winter-ready involves more than just a sturdy roof structure; the insulation must also be able to withstand adverse weather conditions to ensure interior protection.

Inspection and Maintenance

Regular inspection and maintenance are crucial in preparing any warehouse roof for winter. Before the cold season sets in, it is advisable to have professionals assess the existing state of your roof. For warehouses with hotmelt roofing, this usually involves checking the membrane for any signs of damage or wear, ensuring all joints are still intact, and inspecting the insulation underneath the membrane for any moisture penetration.

Installation of Hotmelt Systems

If your current roof is not up to the task of winter weather, consider installing a hotmelt waterproofing system before the season changes. The installation process typically includes the preparation of the roof deck, application of a primer, and the subsequent layered application of the hotmelt membrane. This material is then coated with a protection layer or suitable surfacing, such as paving, to provide an additional shield against environmental elements.

Environmental Considerations

While safeguarding your warehouse, it’s also vital to consider the environmental implications of your choice in roofing material. Hotmelt roof waterproofing is not only efficient in terms of performance but also holds significant eco-friendly advantages.

Reducing Energy Consumption

One of the key benefits of using hotmelt systems is the enhanced energy efficiency they offer. The excellent insulating properties help maintain consistent indoor temperatures, which can significantly reduce the need for artificial heating or cooling. This reduction in energy usage translates into lower utility bills and a smaller carbon footprint for your warehouse.

Recyclability and Sustainability

Hotmelt membranes are often composed of recycled materials, and the system’s overall design supports sustainability due to its longevity and minimal maintenance requirements. By opting for durable solutions, property managers contribute to a more sustainable future through reduced material consumption and waste generation.

Summary

Hotmelt roof waterproofing provides a reliable and efficient solution for warehouse roofs needing winter preparation. Its durability, adaptability, and superior weather resistance are invaluable for maintaining structural integrity and reducing maintenance costs. By choosing hotmelt roofing, warehouse owners can protect their investments against harsh winter conditions, enhance energy efficiency, and contribute to a sustainable environment. Ensure your warehouse is winter-ready with hotmelt technology and experience peace of mind knowing your roof will stand the test of time.