Understanding Hotmelt Roof Waterproofing

In the realm of roof waterproofing solutions, hotmelt systems have emerged as a leading choice for many hall and warehouse owners, developers, and property managers. This innovative technology offers unparalleled durability and efficiency, setting itself apart from conventional insulation methods. The keyword here is „hotmelt roof waterproofing,” and understanding its applications and advantages is crucial for making informed decisions.

How Does Hotmelt Roof Waterproofing Work?

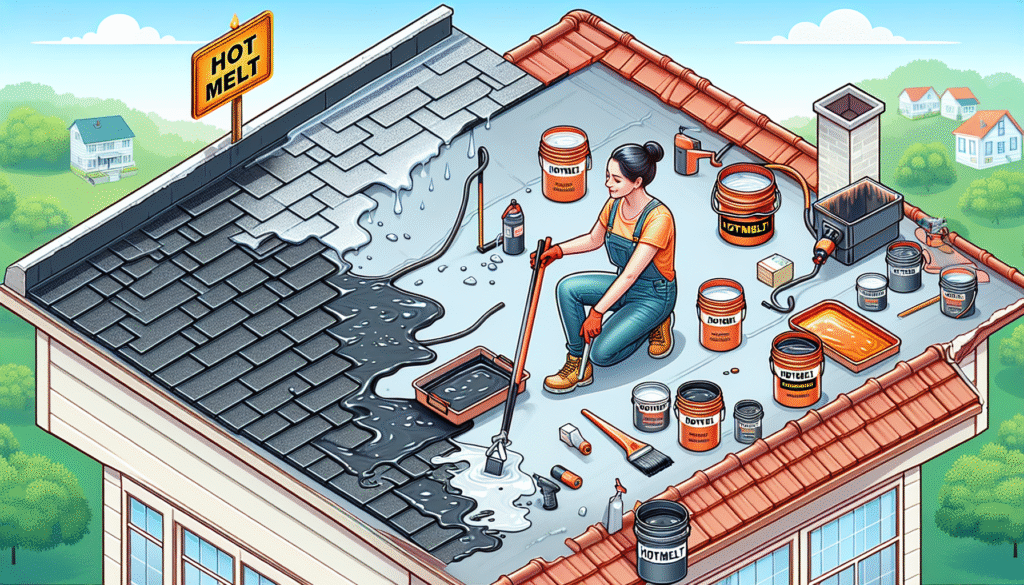

Hotmelt roof waterproofing involves the use of a hot-applied monolithic membrane that provides a seamless and fully adhered waterproof barrier. This material is primarily made up of bitumen, which is modified with a blend of rubber and polymers for enhanced performance. When applied to a roof, the membrane is heated until it becomes fluid and is directly applied, forming a robust, flexible, and long-lasting barrier against water ingress.

The Application Process

The hotmelt system is typically applied in multiple layers to ensure comprehensive coverage and durability. The key steps include:

- Surface Preparation: Ensuring the roof substrate is clean, dry, and free of contaminants.

- Primer Application: Applying a primer to enhance the adhesion of the hotmelt membrane.

- Membrane Application: Heating the hotmelt material to achieve optimal fluidity, then evenly spreading it across the roof surface.

- Protection Layer: Adding a protection layer, often gravel or paving, to guard the membrane against mechanical damage and UV exposure.

Key Advantages

- Seamless Application: Since hotmelt systems are monolithic, there are no seams or joints that could become weak points for water penetration.

- Flexibility: The membrane maintains its flexibility across varying temperatures, reducing the risk of cracking or brittleness.

- Longevity: With proper application, a hotmelt roof waterproofing system can last several decades, offering long-term protection and peace of mind.

Comparing Hotmelt to Other Waterproofing Systems

While various roofing solutions are available in the market, hotmelt stands out due to its distinct advantages over alternatives such as torch-on membranes, single-ply systems, and liquid-applied membranes.

Performance Comparison

- Durability: Hotmelt offers superior durability due to its cohesive application process that eliminates seams.

- Temperature Resistance: Unlike some other systems, hotmelt membranes retain flexibility in extreme temperatures.

- Maintenance: Hotmelt roofs typically require less maintenance and are easier to repair if damaged compared to their counterparts.

Cost Implications

While the initial cost of hotmelt roof waterproofing might be higher than some traditional methods, the return on investment is significant due to its prolonged lifecycle and reduced maintenance needs. This makes it a cost-effective choice in the long run, providing significant savings on potential repairs and replacements.

The Environmental Impact of Hotmelt Roof Waterproofing

As sustainability becomes a growing concern in construction, hotmelt roof waterproofing offers several environmental benefits:

Recyclable and Sustainable

Hotmelt systems are typically recyclable, reducing landfill waste. The materials used are often derived from sustainable sources, making it a greener choice for eco-conscious builders and property managers.

Energy Efficiency

- The insulation properties of hotmelt systems can enhance the energy efficiency of a building, leading to reduced heating and cooling costs.

- Reflective top layers can be added to reduce heat absorption, contributing to lower energy consumption during hot months.

Choosing the Right Contractor for Hotmelt Application

Successful implementation of hotmelt roof waterproofing hinges not only on the quality of materials used but also on the expertise of the contractor. Here are some tips for selecting the right professional for the job:

Experience and Certification

- Ensure the contractor has ample experience and is certified by reputable manufacturers of hotmelt systems.

- Request references and case studies of past projects similar to yours.

Comprehensive Services

A good contractor will offer end-to-end services, including initial consultations, detailed project planning, installation, and post-installation support. This holistic approach ensures high standards are maintained throughout the project lifecycle.

Summary

Hotmelt roof waterproofing stands as a superior insulation solution, offering durability, efficiency, and environmental benefits that far outweigh those of traditional methods. With its seamless application, long lifespan, and excellent performance in diverse conditions, hotmelt is the go-to choice for hall and warehouse owners, developers, and property managers. As sustainability continues to shape the construction industry, the recyclable and energy-efficient nature of hotmelt systems makes them even more appealing. Selecting experienced contractors ensures the system’s full benefits are realized, promising peace of mind and significant long-term savings.