Understanding Hotmelt Waterproofing: A Crucial Solution for Modern Roofs

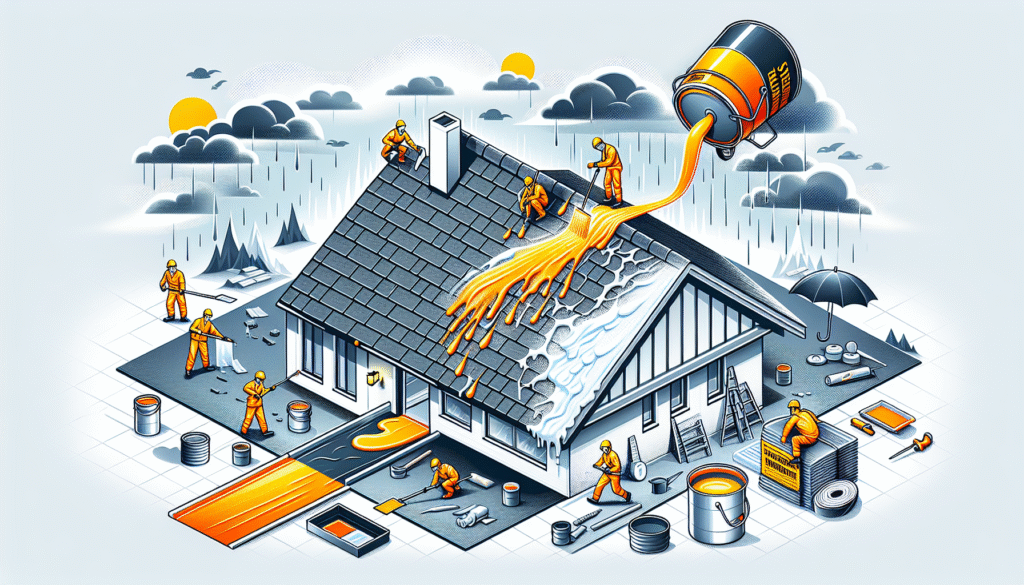

When it comes to protecting your commercial properties like halls and warehouses, effective waterproofing is a non-negotiable aspect. The roofing of such structures is subjected to various weather conditions, which makes it imperative to choose the right waterproofing solution. Hotmelt roofing solutions have emerged as a choice of excellence, promising durability and efficiency. In this article, we delve into the intricacies of hotmelt roofing, shedding light on its superiority over traditional waterproofing methods.

What is Hotmelt Roofing?

Hotmelt roofing is a technology that utilizes a mix of polymers and resins to create a robust waterproof layer. This system is typically applied directly to the roof surface in a molten state, forming a seamless, bonded layer that effectively prevents water penetration. This method is especially suitable for flat or low-pitched roofs often found in large-scale warehouses and industrial halls.

The Components of Hotmelt Roofing

Hotmelt systems generally comprise a blend of polymer-modified bitumen and specialized fabrics. This unique mixture ensures the waterproofing layer is resilient and flexible, adapting to structural movements and temperature fluctuations.

The Application Process

The application of hotmelt involves heating the material until it becomes liquid, then applying it across the roof surface. As it cools, it forms a monolithic membrane that is seamless and void-free, leaving no weak points for water ingress.

Advantages of Hotmelt Waterproofing

Hotmelt roofing has become a preferred solution due to its substantial advantages over conventional methods. Here are some key benefits:

- Durability: Hotmelt systems are known for their long lifespan, often exceeding 25 years, which considerably reduces repair and replacement costs over time.

- Seamlessness: The application process ensures a completely seamless barrier, removing the risk of water ingress that often plagues sectional systems.

- Flexibility: Hotmelt membranes can adapt to structural movements, minimizing the risk of cracks and leaks.

- Cost-effectiveness: When considering the longevity and low maintenance of hotmelt systems, they prove to be a cost-effective solution over their lifecycle.

- Environmental Impact: Many hotmelt products are manufactured with a high recycled content, aligning with green building practices and reducing the carbon footprint.

Comparing Hotmelt with Other Waterproofing Solutions

Traditional Asphalt and Felt Systems

Asphalt and felt systems have been staples for insulating roofs, but they come with limitations such as susceptibility to UV damage and potential seam weaknesses, which can lead to leaks over time. In contrast, hotmelt roofing provides a UV-resistant and seamless solution that mitigates these issues.

Single-Ply Waterproofing

While single-ply membranes offer easy installation, they often lack the robustness and lifespan of hotmelt systems. Single-ply membranes can detach or tear over time, leading to potential water ingress, which is effectively nullified by the monolithic nature of hotmelt systems.

When to Consider Hotmelt Roofing

Hotmelt roofing is suitable for various applications, particularly when managing commercial, industrial, or large residential projects. Consider hotmelt roofing if:

- Your building has a flat or low-pitched roof.

- You seek a long-term solution to minimize ongoing maintenance costs.

- You require a system that can withstand heavy traffic, such as on roofs with foot traffic or equipment installations.

- You value environmentally friendly building practices.

Integration with Green Roofing

One of the notable advantages of hotmelt is its compatibility with green roofing systems. The waterproof layer supports soil substrates and vegetation, enabling property managers to implement sustainable, green roofing solutions without compromising on waterproofing efficacy.

Choosing the Right Contractor

Experience and Expertise

Given the advanced nature of hotmelt roofing systems, it’s crucial to select a contractor with extensive experience in hotmelt applications. Look for certified applicators who demonstrate a thorough understanding of the material and installation techniques.

Portfolio and References

Review potential contractors’ past projects and seek references or testimonials from previous clients. This provides assurance of their capability to deliver high-quality, long-lasting results.

Summary

Hotmelt roofing stands out as a premier choice for commercial property waterproofing, offering unmatched durability, flexibility, and environmental compatibility. This system’s seamless application process eliminates the weak points commonly found in traditional methods, ensuring a long-lasting, robust defense against water ingress. Perfect for flat and low-pitched rooftops, hotmelt roofing solutions not only cut down on long-term maintenance costs but also support sustainable construction practices when integrated with green roofs. As you consider roofing options, choosing an experienced contractor can make a significant difference in achieving optimal results, promising peace of mind for property managers and developers alike.