Understanding Hotmelt Roof Waterproofing

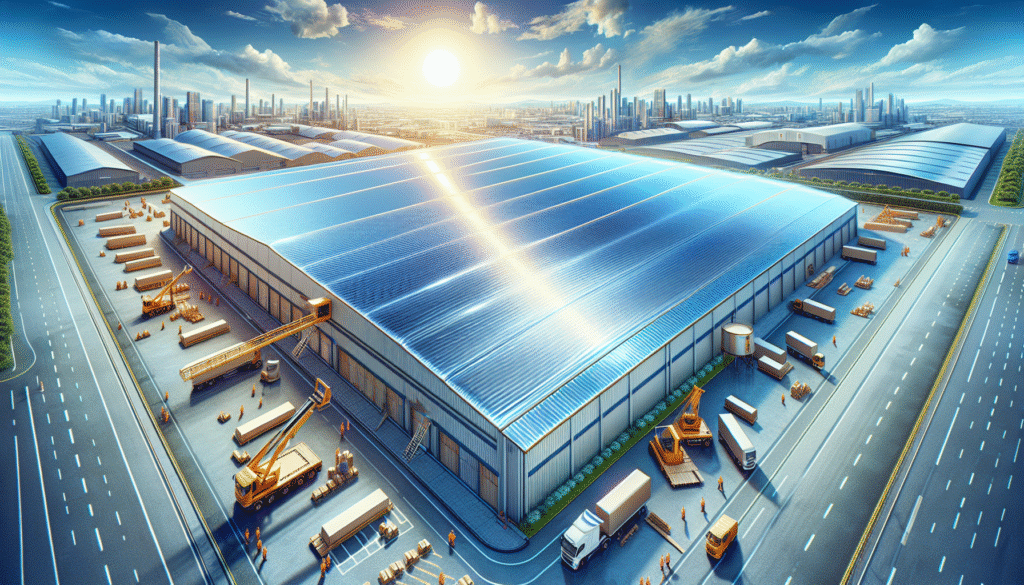

In the realm of roofing solutions, hotmelt roof waterproofing stands out as a robust and dependable choice, particularly for warehouses and industrial spaces. This advanced waterproofing system is designed to protect roofing structures from water damage, thereby extending their lifespan and enhancing their performance. For hall and warehouse owners, developers, and property managers seeking durable insulation solutions, understanding the mechanics and benefits of hotmelt roofing is crucial.

What is Hotmelt Roof Waterproofing?

Hotmelt waterproofing is a bitumen-based roofing system. It employs a mix of polymers and resins, heated until fluid, and then applied in layers to form a seamless, waterproof membrane. This adaptable, monolithic layer conforms to the roof’s surface, providing comprehensive protection against water ingress. As the material cools, it forms a solid layer that is sturdy yet flexible enough to accommodate structural movements, making it ideal for long-term roofing solutions.

Key Components

- Hot Melt Rubberized Compound: This is the core component that forms the waterproofing layer. It is heated prior to application to ensure it properly bonds with the substrate.

- Reinforcement Layer: This usually consists of a polyester or fiberglass layer added for extra strength and durability.

- Protection Boards: These are installed on top of the hotmelt layer to shield it from mechanical damage.

Advantages of Hotmelt Roof Waterproofing

Hotmelt roof waterproofing offers a plethora of advantages that make it a superior choice over other roofing methods like single-ply, liquid-applied systems, and built-up roofing.

Durability and Longevity

The hotmelt system creates a continuous, seamless membrane that naturally resists water penetration and the effects of extreme weather. This durability reduces maintenance needs, thereby lowering long-term costs. The life expectancy of hotmelt roofs often extends beyond 30 years, offering warehouse and industrial facility owners peace of mind regarding their roof’s performance.

Flexibility in Design

Another key advantage of hotmelt waterproofing is its flexibility. The material can easily adapt to various architectural designs, accommodating unusual shapes and intricate structures. This flexibility ensures that all surfaces are thoroughly protected without compromising the aesthetic aspects of the building.

Environmental Benefits

- Low Carbon Footprint: Hotmelt systems use recycled materials, reducing the carbon footprint of the insulation project.

- Energy Efficiency: The reflective surface of hotmelt roofs helps in reducing the building’s heat absorption, contributing to energy savings.

Cost-Effectiveness

While the initial setup costs of hotmelt systems can be higher than some traditional roofing methods, the long-term cost-effectiveness of this solution is evident in its durability and minimal maintenance requirements.

Suitable Applications for Hotmelt Roof Waterproofing

Understanding where and how hotmelt roof waterproofing is best applied can help property managers and developers make informed decisions.

Flat Roofs

Hotmelt systems are best-suited for flat or low-slope roofs typical in warehouses and industrial buildings. The seamless application eliminates potential points of water entry, a common problem with traditional flat roofing methods.

Green Roofs

For those looking to incorporate green spaces atop their buildings, hotmelt roof systems provide the perfect waterproof base. Their moisture resistance ensures that plant growth on the roof does not compromise the integrity of the roofing structure.

Installation Process

The installation of a hotmelt roof waterproofing system is a sophisticated process that should be handled by trained professionals to ensure optimal results.

Surface Preparation

Before application, the roof surface must be cleaned and primed to enhance adhesion. Any irregularities must be repaired to provide a clean, even substrate for the hotmelt material.

Application and Finishing

Once prepared, the hotmelt material is heated and applied evenly across the roof surface in layers. Each layer is embedded with a reinforcement layer to maximize strength. Finally, a layer of protection boards is installed to guard against mechanical damage.

Summary

Hotmelt roof waterproofing stands as a formidable choice for those seeking a long-lasting and resilient roofing solution. Its seamless application, durability, and cost-effectiveness make it ideal for warehouses, industrial buildings, and structures with flat or green roofs. Despite the higher initial cost, its low maintenance requirements and extended lifespan offer unparalleled value. For developers, property managers, and owners, investing in this advanced roofing technology can ensure efficient protection against the elements for decades.